In this post I publish some user comments that tell how eagleUp could help by saving time and money.

Take vertical measurements

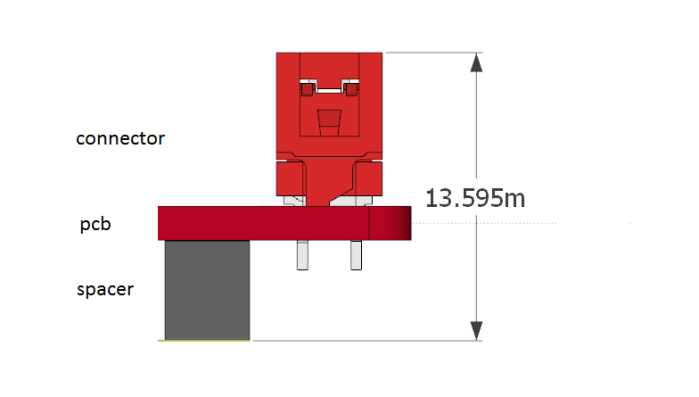

Measuring in the PCB plane is simple, but when it comes to vertical dimensions, the designer often has to read datasheets and to make estimation for the missing dimensions. With eagleUp, you simply assemble the parts as you would do with the prototype, and then take measurements with a virtual ruler. Quick and accurate !

In the example below, Joe needed to know the height of spacer necessary for the mounting of the PCB on the enclosure floor, and the total height. He used the import procedure to get an accurate model of the male and female parts of the wire to board connector. The result appeared immediatly.

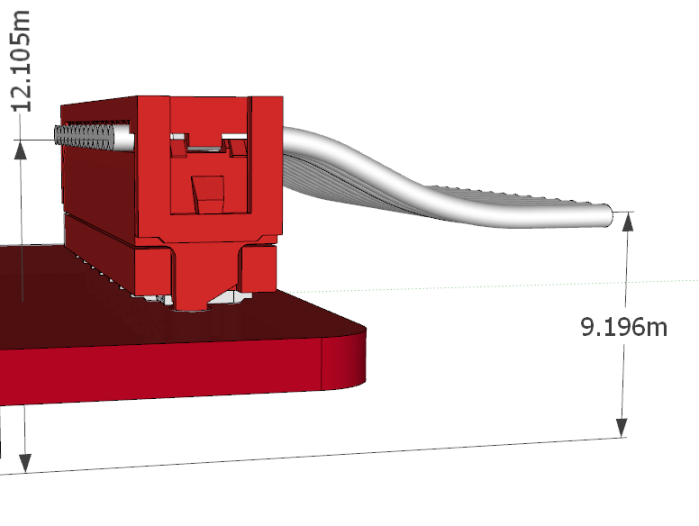

Then he needed to determine the path of the ribbon cable. The position of the ribbon was not indicated in the datasheet of the connectors, so he added a virtual ribbon cable, and could shape it to match the future location of the cables in the enclosure.

Then he needed to determine the path of the ribbon cable. The position of the ribbon was not indicated in the datasheet of the connectors, so he added a virtual ribbon cable, and could shape it to match the future location of the cables in the enclosure.

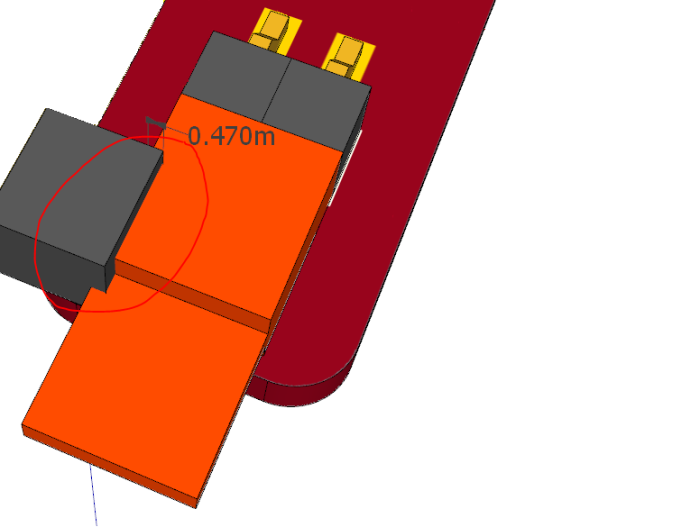

Detect collision in time

Before launching the circuit into production, Joe had a last look at the model, and saw something wrong. There was a collision between a spacer and a jumper. The jumper was added quickly at the end of the project and appeared fitting on the Eagle design. The mistake came from the spacer that did not appear in Eagle, as previously it was a completely empty area.

The mistake was detected on time and corrected, and the schedule was kept.

(Feel free to share your experiences in the comments or by email)

“Detect collision in time”

If you have the SketchUp 8 pro version,you can check collisions with the SuSolid plugin (www.susolid.com).